Our Capabilities

Aerospace and Defense Complex Machining and Fabrication.

With 155,000 sq ft and top of the line OKUMA machine tools, DSM Precision delivers turnkey production solutions that are scalable from development to full rate in Brownsburg, Indiana.

Airframe

Jet Engine

Radar and Sensors

Missiles and Launchers

High Performance Race Engines

Certifications.

AS9100 Rev D

NIST 800-171: CMMC Level 2

ITAR

Highlight Programs.

-

Boeing KC-135 Horizontal Stabilizer

Complex machined large steel terminal fittings and other aluminum airframe components including turnkey specialty outside processing such as Boeing approved heat treat and finishing requirements.

-

Kratos | GE: GEK800 Turbo Fan

Development to production support for hard and soft metal machined and fabricated hardware hard and soft metal across cases, generator rotors, shourds, nose cones and other high speed rotating and complex assembly hardware.

-

SPY-6 EASR Radar- Inner Wall Details

Large 120"x40"x8" (zero defect) detail with over 1500 machined features and 264 holes with 0.008" true position GD&T.

-

F-35: L3Harris EODAS Vision Cooler

Medium production complex details with 0.0005" tolerances demonstrating our strengths in Swiss, turning, and ID honing across Stainless steels and other similar metallics.

-

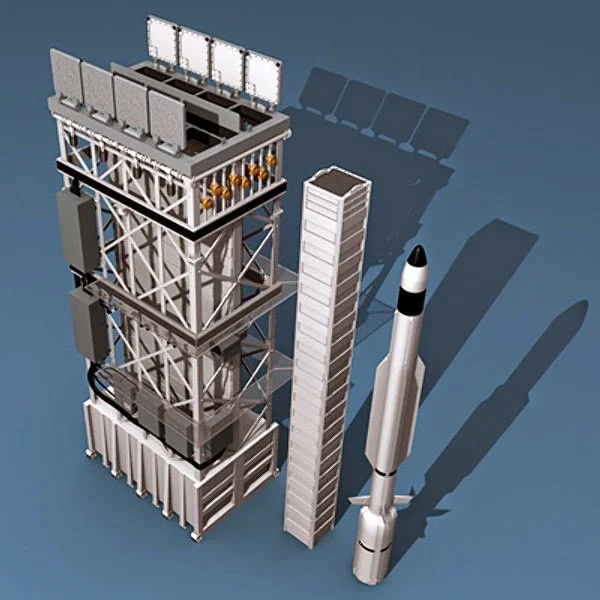

Lockheed Martin Naval Vertical Launch System

Heavy steel machined frame structure details.

-

B-21 Bomber Airframe Details

Titanium and soft metal details across various airframe assemblies.

Let Us Call You Back.

Please provide a good email and call back number and we will follow up ASAP.

Tier 1 Manufacturing Solutions.

-

Precision Machining & Assembly

- 3/4/5 Axis Milling

- Multi Axis Turning, Mill-Turn, & SWISS

- Complex Small/Medium/Large up to 190 × 120 × 54”

- Most hard and soft material types including titanium and inconels.

-

Specialty Outside Processing

- Domestic sourcing for all major specialty outside processes including heat treat, balancing, coatings, and finishing.

- Boeing, Rolls Royce, GE, Northrop and other Prime approved vendor sourcing.

- Subcontracting for other conventional processes

-

Advanced Engineering Services

- Process Engineering

- Design for Manufacturability

- 3D Scanning and Reverse Engineering

- Fixture and workholding

- Prototype and Product Development

Contact us

Contact us for more information or to request a quote.